ILSA is a world reference in the search for and transformation of renewable raw materials into high-performance products for modern agriculture.

The company has a fully equipped research and development center in Vicenza (Italy) that develops advanced scientific projects in partnership with leading universities in Europe, the USA and Brazil.

Discover the transformation technologies used in our portfolio below:

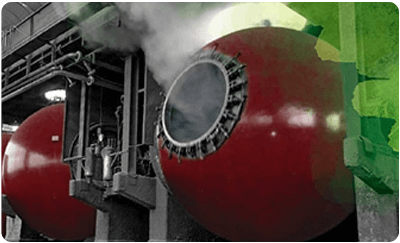

This know-how is used to obtain AZOGEL®, hydrolyzed gelatin for agricultural use. The process takes place in dynamic autoclaves, and is carried out in three successive phases of different and controlled duration and temperature. This technology allows for a homogeneous product without variations, characterized mainly by having a pre-established pattern of protein chains (a natural source of amino acids), thus promoting a gradual release of nitrogen, mediated by soil microorganisms.

Process that consists of enzymatically hydrolyzing natural substances of plant and animal origin. This technology is used to obtain ILSA liquid products, mainly the GELAMIN® matrix. The raw materials enter the reactors together with water and enzymes capable of breaking the protein chains in predetermined places, releasing the amino acids, polypeptides and peptides. The reaction occurs at a low temperature (between 50-55ºC) inside static reactors. The polypeptide chains are attacked by a group of specific enzymes that “cut” these bonds in a targeted and replicable manner. Thus, the amino acids are not affected and appear in their natural levorotatory form – biologically active and immediately available to plants. After hydrolysis, the vacuum concentration process begins to extract excess water.

HP + M ILSA technology allows the association of an exclusive organic material based on hydrolyzed proteins (a natural source of amino acids) and mineral components in a single pellet. The organic material acts as a conditioner in the fertilizer, allowing water to enter the interior of the pellet, retaining moisture and dissolving the mineral nutrient in a high CTC environment. The nutrients from the organic fraction are supplied to the plants gradually and according to the microorganisms in the soil.

The extraction of bioactive substances from plant matrices is carried out using carbon dioxide (CO2) as an extraction fluid under supercritical conditions. The plant raw materials are dried, ground and immersed in the equipment together with carbon dioxide. The solvent power of CO2 can be regulated by increasing or decreasing the pressure and/or temperature in the extraction chambers, appropriately modifying the pressure conditions (which can reach up to 1000 bar) and temperature (never higher than 80ºC). This process allows the creation of unique, highly selective extracts, with different levels of oils, waxes and desirable extracts. Once this extraction phase is over, the pressure is reduced and the CO2 loses its strength as a solvent, releasing the extracted substances in concentrated form. The extracts obtained are biologically stable and do not require preservatives. This allows extraction without the raw materials suffering thermal stress and without the use of organic or chemical solvents.

Perfil Energia has been in the energy market for over 18 years, serving customers from various regions of Brazil. Through its SUSTAINABLE PROFILE program, it certifies organizations by accounting for greenhouse gas (GHG) emissions regulated by the Kyoto Protocol that will no longer be emitted by the customer who joins the free contracting environment (ACL).

ILSA BRASIL aims to transform the way we preserve and feed the planet, seeking to develop our products in a sustainable way, contributing to the healthy growth of the market in which we operate. In this way, we have joined the SUSTAINABLE PROFILE PROGRAM, which allows us to meet two sustainable development goals established by the UN:

7 – Clean and affordable energy

11 – Sustainable cities and communities

12 – Responsible consumption and production

13 – Action against global climate change

In 20223, with the purchase of energy in the Free Contracting Environment, originating from renewable sources, we stopped emitting:

56,317 t of CO², the equivalent of 2,559 trees planted